|

|

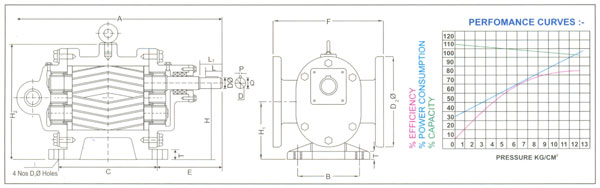

PG Series-Features:

- Single Helical Gears

- Hardened & Ground Shafts.

- Max. Capacity-500 Lpm

- Max. Pressure- 10 Kg/cm²

- Max. Temperature-80 degree C

- Modified Version For High Temp. Up To-200 degree C

- Modified Version For Molasses and Vacuum Application

- Higher Aesthetic Value

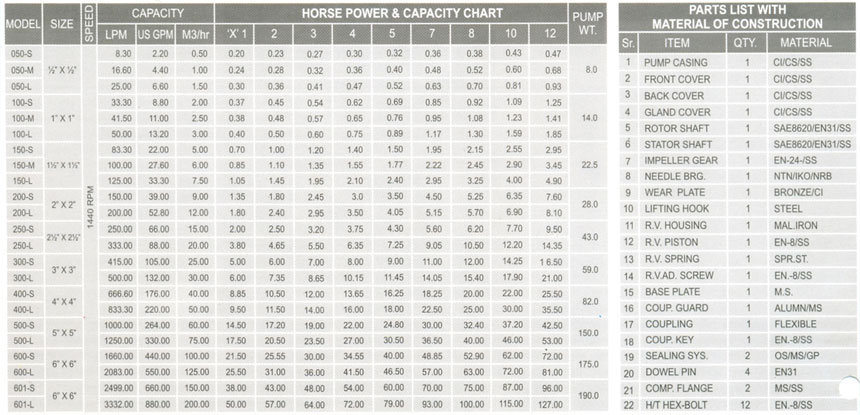

Horse Power And Capacity Chart:

| Pump Model |

Inlet Outlet Size |

Capacity |

Recommended Motor HP At Differential Pressure Of 'X' kg/ cm² With 1500 SSU Viscosity & Specific Gravity @ 0.8g/CC |

WT. of Bare Shaft Pump in KG. |

| LPM |

US GPM |

M3/hr |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

| PG-050 |

½"x½" |

20 |

5.30 |

1.20 |

|

2.80 |

| PG-075 |

¾"x¾" |

30 |

7.92 |

1.80 |

|

4.50 |

| PG-100 |

1"x1" |

50 |

13.20 |

3.00 |

|

6.20 |

| PG-125 |

1¼"x1½" |

75 |

19.80 |

4.50 |

|

8.50 |

| PG-150 |

1½"x1½" |

110 |

29.00 |

6.60 |

|

10.50 |

| PG-200 |

2"x 2" |

225 |

59.40 |

13.50 |

|

18.00 |

| PG-250 |

2½"x2½" |

350 |

92.50 |

21.00 |

|

27.30 |

| PG-300 |

3"x3" |

500 |

131.60 |

30.00 |

|

37.00 |

|

|

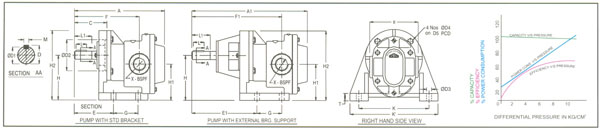

Dimension:

| Model |

A |

B |

E |

F |

G |

S |

T |

H |

H1 |

H2 |

H3 |

L |

M |

N |

DØ |

D1Ø |

K |

BØ |

| PG-050 |

152 |

32 |

51.0 |

40 |

70 |

90 |

70 |

63 |

50.0 |

95 |

8 |

22.0 |

4 |

13.5 |

12 |

8 |

70 |

½BSP |

| PG-075 |

182 |

37 |

63.5 |

45 |

85 |

110 |

80 |

80 |

66.0 |

118 |

8 |

25.0 |

5 |

16.0 |

14 |

10 |

80 |

3/4" BSP |

| PG-100 |

204 |

46 |

64.5 |

50 |

93 |

127 |

95 |

93 |

76.0 |

138 |

10 |

27.5 |

5 |

19.0 |

17 |

10 |

90 |

1"BSP |

| PG-125 |

238 |

48 |

75.0 |

60 |

105 |

140 |

110 |

100 |

80.5 |

145 |

10 |

32.0 |

6 |

22.5 |

20 |

12 |

100 |

1¼" BSP |

| PG-150 |

256 |

60 |

80.0 |

70 |

115 |

150 |

130 |

110 |

88.0 |

155 |

12 |

35.0 |

6 |

24.5 |

22 |

12 |

108 |

1½" BSP |

| PG-200 |

324 |

78 |

92.0 |

100 |

140 |

180 |

160 |

132 |

105.0 |

192 |

15 |

40.0 |

8 |

28.0 |

25 |

15 |

142 |

2"BSP |

| PG-250 |

380 |

85 |

110.0 |

120 |

155 |

200 |

185 |

145 |

113.0 |

215 |

18 |

45.0 |

8 |

31.0 |

28 |

17 |

160 |

2½" BSP |

| PG-300 |

425 |

105 |

120.0 |

140 |

180 |

235 |

205 |

160 |

125.0 |

238 |

20 |

50.0 |

8 |

33.0 |

30 |

17 |

170 |

3"BSP |

|

| SR.NO |

PART |

MOC. |

Viscosity |

Speed |

Capacity |

| 1 |

CASING |

C.I GR. 20 |

UP TO 500CST |

1500RPM |

100% |

| 2 |

R.V COVER |

C.I GR. 20 |

500-1500 CST |

1000RPM |

66% |

| 3 |

GLAND COVER |

C.I GR. 20 |

1500-5000CST |

750RPM |

50% |

| 4 |

SHAFTS |

EN-9 H &G |

5000-15000 |

500RPM |

33% |

| 5 |

GEARS |

EN-8 |

15000-30000CST |

380RPM |

25% |

| 6 |

GLAND SEAL |

OIL SEAL |

30000-50000CST |

300RPM |

20% |

| 7 |

SHAFT BRG |

SINTRED BRONZE BUSH |

50000-100000CST |

200RPM |

13% |

| 8 |

R.V PLUG |

BRASS/M.S/ALLUMINIUM |

100000-200000 |

150RPM |

10% |

|

| |

|

|

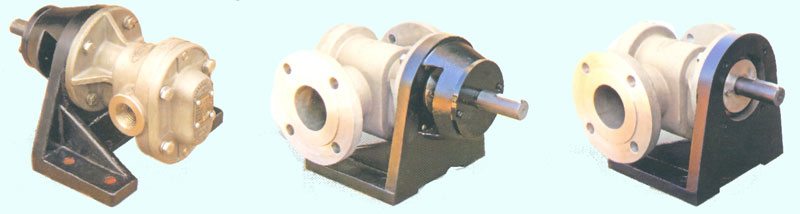

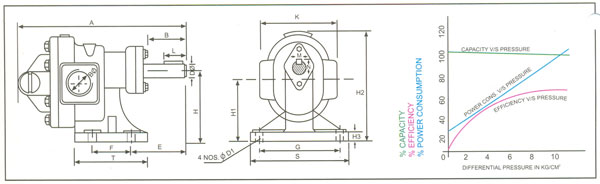

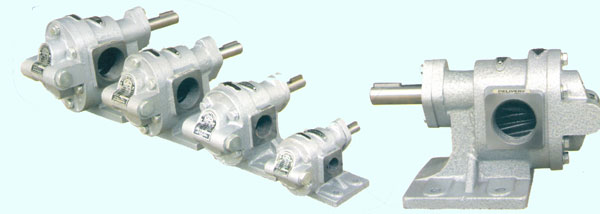

PGX Series-Features:

- Reliable for Transfer of :

- Viscous & Semi-viscus Liquids like LDO, FO, HSD, Lubricating Oils etc.

- Compact & Highly useful for Standardizing on :

- Centralized Lubricating System

- Pumping & Heating System

- Oil Filtration & Cleaning System

- Transformer Oil Purification System

- Wide Capacity Range

- Optionally Converted to Foot type with the help of L type

Bracket which Matches with the Frame of Electrical Motor.

- Option of External Ball Bearing Support to Drive Shaft.

|

Horse Power And Capacity Chart:

| Pump Model |

Inlet Outlet (B.S.P.) |

Capacity at 1500 RPM |

Power Consumption(B.H.P) at Diff. Pressure (kg/ cm²) With Liquid Viscosity @ 1500 SSU of Specific Gravity @ 0.8gm/CC |

Weight of pump with STD bracket |

Weight of pump with ex. BRG. bracket |

| LPM |

US GPM |

M³/HR |

|

| PGX-025-S |

¼"x¼" |

2.5 |

0.66 |

0.15 |

|

2.20 |

3.00 |

| PGX-025-L |

5 |

1.3 |

0.30 |

| PGX:050-S |

½"x½" |

10 |

2.65 |

0.60 |

|

3.00 |

4.00 |

| PGX:050-L |

15 |

4.00 |

0.90 |

| PGX:0.75-S |

¾"x¾" |

20 |

5.30 |

1.20 |

|

4.0 |

5.25 |

| PGX:0.75-L |

25 |

6.65 |

1.50 |

| PGX:100-S |

1"x1" |

35 |

9.30 |

2.10 |

0.50 |

0.75 |

1.00 |

0.75 |

1.00 |

1.50 |

2.00 |

|

6.00 |

7.50 |

| PGX:100-L |

50 |

13.30 |

3.00 |

| PGX:125-S |

1¼"x1¼" |

60 |

16.00 |

3.60 |

|

8.25 |

10.00 |

| PGX:125-L |

75 |

19.80 |

4.50 |

| PGX:150-S |

1½"x1½" |

90 |

23.79 |

5.40 |

1.50 |

2.00 |

3.50 |

1.50 |

2.00 |

3.00 |

5.00 |

|

11.00 |

13.50 |

| PGX:150-L |

110 |

29.00 |

6.60 |

| PGX:200-S |

2"x2" |

150 |

40.00 |

9.00 |

2.00 |

3.00 |

5.00 |

3.00 |

5.00 |

7.50 |

|

17.00 |

19.00 |

| PGX:200-L |

200 |

53.30 |

12.00 |

| PGX:250-S |

2½"x2½" |

300 |

80.00 |

18.00 |

|

26.00 |

29.00 |

| PGX:250-L |

350 |

92.50 |

21.00 |

| PGX:300-S |

3"x3" |

415 |

110.00 |

25.00 |

|

35.00 |

40.00 |

| PGX:300-L |

500 |

132.00 |

30.00 |

|

|

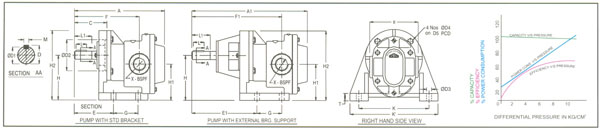

Dimension: Bare Shaft Pump, Pump with Standard Bracket and Pump with External Bearing Support Bracket:

| Model |

A |

B |

C |

ØD2 |

ØD4 |

ØD5 |

ØD1 |

D |

M |

L |

L1 |

E |

G |

K |

K' |

F |

H |

H1 |

H2 |

T |

ØD3 |

A1 |

E1 |

F1 |

X |

| PGX-025 |

117 |

60 |

28 |

45 |

6.50 |

56 |

10 |

11.50 |

3 |

12 |

14 |

41 |

35 |

100 |

126 |

73 |

63 |

54 |

100 |

10 |

8.50 |

166 |

90 |

122 |

¼BSP |

| PGX-050 |

166 |

70 |

51 |

50 |

8.50 |

66 |

12 |

13.50 |

4 |

22 |

32 |

64 |

40 |

115 |

138 |

108 |

71 |

59 |

113 |

12 |

8.50 |

211 |

109 |

153 |

½BSP |

| PGX-075 |

184 |

80 |

54 |

60 |

10.00 |

80 |

12 |

13.50 |

4 |

22 |

40 |

69 |

45 |

125 |

153 |

123 |

80 |

66 |

132 |

15 |

10.00 |

242 |

127 |

181 |

¾BSP |

| PGX-100 |

202 |

86 |

62 |

60 |

10.00 |

80 |

15 |

17.00 |

5 |

28 |

40 |

77 |

45 |

125 |

153 |

128 |

80 |

63 |

132 |

15 |

10.00 |

260 |

135 |

186 |

1" BSP |

| PGX-125 |

222 |

100 |

67 |

70 |

10.00 |

90 |

20 |

22.50 |

6 |

31 |

45 |

84 |

50 |

150 |

180 |

139 |

90 |

71 |

146 |

15 |

12.00 |

280 |

142 |

197 |

1.1¼" BSP |

| PGX-150 |

251 |

108 |

75 |

75 |

12.50 |

98 |

20 |

22.50 |

6 |

35 |

50 |

93 |

65 |

160 |

190 |

160 |

100 |

78 |

160 |

15 |

12.00 |

313 |

155 |

222 |

1.1½" BSP |

| PGX-259 |

307 |

140 |

92 |

85 |

13.50 |

110 |

25 |

28.00 |

8 |

40 |

62 |

108 |

80 |

190 |

230 |

197 |

112 |

85 |

181 |

15 |

15.00 |

369 |

170 |

259 |

2" BSP |

| PGX-250 |

366 |

157 |

98 |

100 |

13.50 |

125 |

25 |

28.00 |

8 |

45 |

62 |

117 |

110 |

216 |

256 |

231 |

132 |

100 |

210 |

18 |

17.00 |

423 |

174 |

288 |

2.½" BSP |

| PGX-300 |

407 |

170 |

106 |

110 |

13.50 |

143 |

30 |

33.00 |

8 |

49 |

70 |

128 |

135 |

260 |

306 |

248 |

160 |

126 |

249 |

20 |

19.00 |

472 |

193 |

313 |

3"BSP |

|

| SR.NO |

PART |

MOC. |

Viscosity |

Speed |

Capacity |

| 1 |

CASING |

CI GR. 20 |

UP TO 500CST |

1500RPM |

100% |

| 2 |

R.V COVER |

CI GR. 20 |

500-1500 CST |

1000RPM |

66% |

| 3 |

GLAND COVER |

CI GR. 20 |

1500-5000CST |

750RPM |

50% |

| 4 |

SHAFTS |

EN-9 H &G |

5000-15000 CST |

500RPM |

33% |

| 5 |

GEARS |

EN-8 |

15000-30000CST |

380RPM |

25% |

| 6 |

GLAND SEAL |

OIL SEAL |

30000-50000CST |

300RPM |

20% |

| 7 |

SHAFT BRG |

SINTRED BRONZE BUSH |

50000-100000CST |

200RPM |

13% |

| 8 |

R.V PLUG |

BRASS/M.S/ALLUMINIUM |

100000-200000CST |

150RPM |

10% |

|

| |

|

|

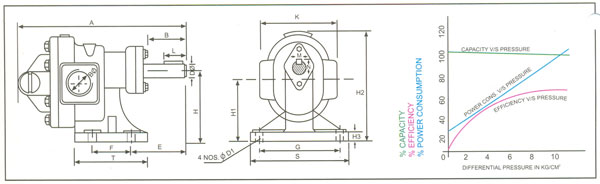

PGSS Series-Applications:

- Chemical Industry

- Pharmaceutical Industry

- Dyeing & Printing Houses

- Food & Beverages .

Features:

- Complete SS -316 (CF8M) Investment Casting

- Nitrided Gears and Shafts for longer life

- Teflon Coated Bush for Smooth Performance

- Optimum Internal Clearance for Accurate Capacity and Lower Power Consumption

- Double Helical Gear Design From SS-100 Onwards.

|

|

Horse Power And Capacity Chart:

| Pump Model |

Inlet Outlet (B.S.P.) |

Capacity at 1500 RPM |

Power Consumption(B.H.P) at Diff. Pressure (kg/ cm²) With Liquid Viscosity @ 1500 SSU of Specific Gravity @ 0.8gm/CC |

Weight of pump with STD bracket |

Weight of pump with ex. BRG. bracket |

| LPM |

US GPM |

M³/HR |

|

| PGSS-025-S |

¼"x¼" BSP |

2.5 |

0.65 |

0.15 |

|

2.20 |

3.00 |

| PGSS-025-L |

5 |

1.30 |

0.30 |

| PGSS:050-S |

½"x½" BSP |

10 |

2.65 |

0.60 |

|

3.70 |

4.70 |

| PGSS:050-L |

25 |

6.65 |

1.50 |

| PGSS:0.75 |

¾"x¾" BSP |

35 |

9.30 |

2.10 |

|

4.25 |

5.50 |

| PGSS:100 |

1"x1" BSP |

50 |

13.30 |

3.00 |

|

5.25 |

6.50 |

| PGSS:150-S |

1½"x1½" BSP |

75 |

20.00 |

4.50 |

|

10.50 |

13.00 |

| PGSS:150-L |

100 |

26.60 |

6.00 |

| PGSS:200-S |

2"x2" BSP |

150 |

40.00 |

9.00 |

|

15.70 |

18.00 |

| PGSS:200-L |

200 |

53.30 |

12.00 |

| PGSS:250-S |

2½"x2½" BSP |

300 |

80.00 |

18.00 |

|

25.00 |

28.00 |

| PGSS:250-L |

350 |

92.50 |

21.00 |

| PGSS:300-S |

3"x3" FLANGED |

415 |

110.00 |

25.00 |

7.50 |

10.00 |

12.50 |

15.00 |

7.50 |

10.00 |

12.50 |

15.00 |

20.00 |

|

|

45.00 |

48.50 |

| PGSS:300-L |

500 |

132.00 |

30.00 |

|

|

Dimension: Bare Shaft Pump, Pump with Standard Bracket and Pump with External Bearing Support Bracket:

| Model |

A |

B |

C |

Ø0D2 |

ØD4 |

ØD5 |

ØD1 |

D |

M |

L |

L1 |

E |

G |

K |

K' |

F |

H |

H1 |

H2 |

T |

ØD3 |

A1 |

E1 |

F1 |

X |

| PGSS-025 |

106 |

56 |

33 |

45 |

6.5 |

56 |

10 |

11.5 |

3 |

12 |

14 |

46 |

35 |

100 |

125 |

74 |

63 |

54 |

100 |

10 |

8.5 |

151 |

91 |

119 |

¼BSP |

| PGSS-050 |

145 |

76 |

53 |

50 |

8.5 |

66 |

12 |

13.5 |

4 |

20 |

32 |

66 |

40 |

115 |

138 |

105 |

71 |

57 |

113 |

12 |

8.5 |

185 |

106 |

145 |

½BSP |

| PGSS-075 |

158 |

82 |

62 |

60 |

10.00 |

80 |

15 |

17.00 |

5 |

28 |

40 |

77 |

45 |

125 |

146 |

115 |

62 |

63 |

132 |

15 |

10.00 |

218 |

137 |

174 |

¾BSP |

| PGSS-100 |

173 |

82 |

62 |

60 |

10.00 |

80 |

15 |

17.00 |

5 |

28 |

40 |

77 |

45 |

125 |

146 |

124 |

80 |

63 |

132 |

15 |

10.00 |

233 |

137 |

184 |

1" BSP |

| PGSS-150 |

224 |

98 |

71 |

75 |

12.5 |

98 |

20 |

22.5 |

6 |

35 |

50 |

89 |

65 |

160 |

190 |

153 |

100 |

78 |

160 |

15 |

12.00 |

285 |

150 |

214 |

1.5" BSP |

| PGSS-200 |

258 |

115 |

88 |

85 |

13.5 |

110 |

25 |

28.00 |

8 |

40 |

62 |

104 |

80 |

190 |

230 |

180 |

112 |

85 |

181 |

15 |

15.00 |

328 |

174 |

250 |

2" BSP |

| PGSS-250 |

297 |

130 |

83 |

100 |

13.5 |

125 |

25 |

28.00 |

8 |

45 |

60 |

102 |

110 |

216 |

256 |

194 |

132 |

100 |

210 |

18 |

17.00 |

364 |

170 |

262 |

2.5" BSP |

| PGSS-300 |

352 |

280 |

94 |

110 |

13.5 |

143 |

30 |

33.00 |

8 |

50 |

70 |

116 |

135 |

195 |

240 |

232 |

160 |

126 |

249 |

20 |

19.00 |

424 |

188 |

304 |

3"FLG |

|

| Sr. |

PART |

MATERIAL |

| 1 |

BODY |

SS-316 (CF 8M Casting) |

| 2 |

COVER |

SS-316 (CF 8M Casting) |

| 3 |

GEARS |

SS-316 Nitrided |

| 4 |

SHAFTS |

SS-316 Nitrided |

| 5 |

GLAND COVER |

SS-316 |

| 6 |

SEAL |

PTFE/Z-Pac/ Mech. Seal |

| 7 |

BRACKET |

C.I.-20 |

| 8 |

BUSH |

PTFE Coated |

| 9 |

BOLT |

SS-304 |

| 10 |

RELIEF VALVE (OPTIONAL) |

SS-316 |

|

| Recommended For Liquids |

| Viscous and Corrosive chemicals |

| Mild Acids |

| Printing Inks |

| Dyes |

| Sugar Syrups |

| Resins & Pigments |

| Slurry(Non-abrasive) |

| Glycerine |

| Vegetable Oils |

| |

|

| Viscosity |

Speed |

Capacity |

| UP TO 500CST |

1500RPM |

100% |

| 500-1500 CST |

1000RPM |

66% |

| 1500-5000CST |

750RPM |

50% |

| 5000-15000 CST |

500RPM |

33% |

| 15000-30000CST |

380RPM |

25% |

| 30000-50000CST |

300RPM |

20% |

| 50000-100000CST |

200RPM |

13% |

| 100000-200000CST |

150RPM |

10% |

|

|